JN15-D-12/31.5 Indoor High voltage Electric Motorized Earthing switch Grounding switch from JUCRO

JN15-D-12/31.5 indoor high-voltage electric earthing switch is a new type of earthing switch designed and developed by our company according to the market needs. It is suitable for indoor 3-12KV three-phase AC 50(60) Hz power system and various types of high-voltage switchgear supporting use. It can also be used for system grounding during maintenance of high-voltage electrical equipment. And can be used in unattended and intelligent substation.

The product conforms to national standard GB1985-2004 "AC high voltage disconnector and earthing switch" and IEC 62271-102-2002. The earthing switch has the advantages of simple and compact structure, light weight, flexible operation, convenient installation, good dynamic and thermal stability, and reliable motorized operation.

As the earthing switch is electric operation, so the manual operation of the chain on the cabinet is consistent with the original style, but some parts have been modified, be sure to use the company's matching chain parts, otherwise the motor of the earthing switch will be burnt down.

If the back door of the middle cabinet needs to have a corresponding interlock with the motorized earthing switch, it must also use our patented technology to install a backdoor interlock, and equip with a travel switch, when the back door is not closed, cut off the operating power of the motorized earthing switch, in order to avoid damage to the motor due to the wrong operation of the electric earthing switch.

When connecting by electrical interlock with the earthing switch, be sure to use the auxiliary contacts of the associated electrical components to disconnect the operating power supply of the earthing switch to achieve electrical interlock. To ensure the reliability of the electrical interlock.

1. The altitude does not exceed 1000m:

2. Ambient air temperature: +40°C ~ -20°C;

3. The earthquake intensity does not exceed 8 degrees;

4. The daily average relative humidity is not more than 95%, and the monthly average is not more than 90%:

5. There shall be no gas, steam, chemical precipitation, smoke, dust, dirt and explosive erosive substances which seriously affect the insulation and conductivity of the earthing switch in the installation site;

6. Frequent and violent vibration shall not exist in the installation site.

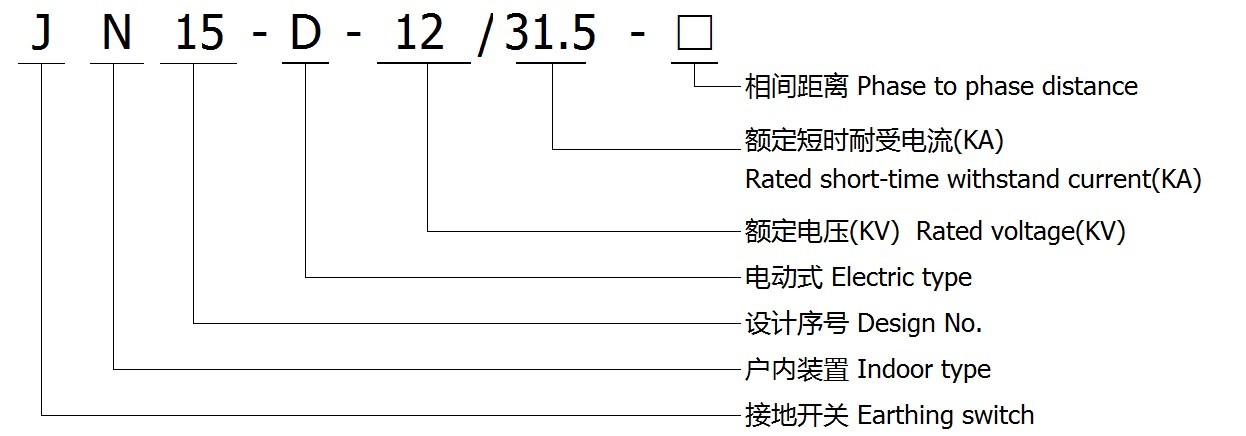

CODING RULES

Item |

Unit |

Data |

|

Rated voltage | KV | 12 | |

Rated short-time withstand current | KA | 31.5 | |

Rated withstand current(peak value) | KA | 80 | |

Rated short-circuit making current |

KA |

80 |

|

Rated insulation level |

Power

frequency withstand voltage(1 min) |

KV |

42 |

Lightning

impulse voltage | KV | 75 | |

The fracture distance after opening is not less than | mm | 125 | |

Control voltage |

V |

AC/DC220V

DC110V |

|

MAIN STRUCTURE

The earthing switch is mainly composed of bracket, grounding knief, fixed contacts, sensor, shaft, crank, press spring, conductive bushing and flexible connection. The bracket is made of thin steel plate, bent and welded into parts and the rest are assembled parts.

WORKING PRINCIPLE

When manually make the earthing switch closing, make main shaft torque to overcome the resistance moment, driven in turn arm along the explaining of direction, and make the joystick on the grounding knife through compression spring dead point, pressure spring release energy, make the earth began to close fast switching, in explaining of position, grounding knife components on the knife by butterfly spring and static contact of flange (edge) solid contact in a reliable way.

When manual switching operation, the acting torque enables the spindle to overcome the resistance moment and the spring force, and drives the crank arm to rotate along the square sentence of switching, and makes the grounding knife press spring pass the dead point, the press spring energy storage ends, in order to prepare for the next closing.

When operating electrically, there is a driving device composed of gear, reducer, motor and control plate in the ground switch. The device outputs torque in the positive and negative directions, making the ground switch off or close.

Whether the ground opening is operated manually or electrically has nothing to do with the closing and opening speed of the ground opening.

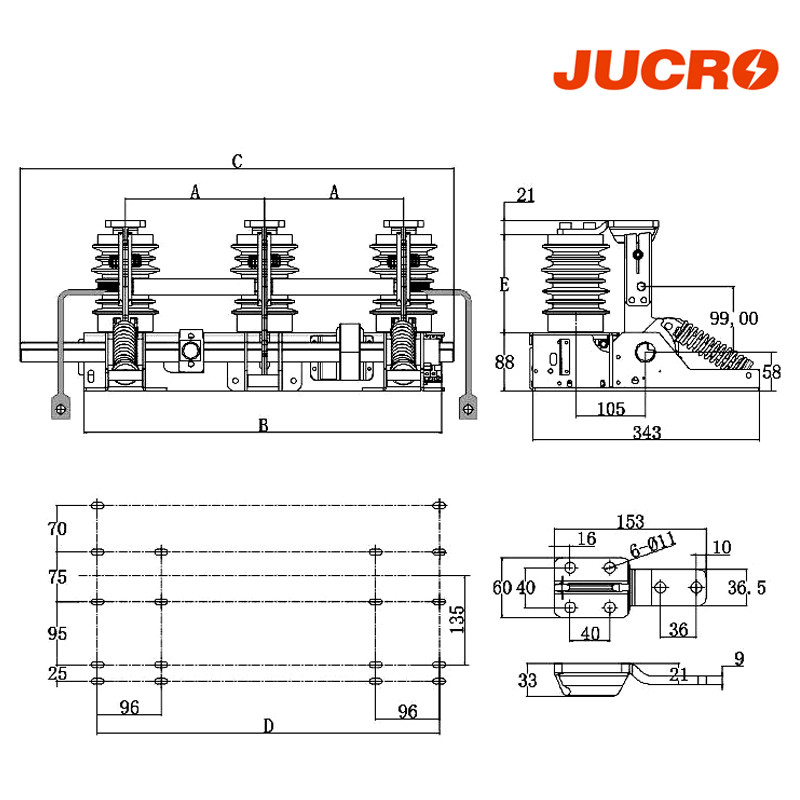

|

Model

|

Phase to phase distance A

|

Holder B

|

principal axis C | pitch-row D |

The height of the sensor for plateau type E

|

|

JN15-D-12/31.5-150

|

150

|

424

|

535 | 396 |

Below 1000 meters 145 Below 2000 meters 170 Below 3000 meters

185 |

|

JN15-D-12/31.5-165

|

165

|

454

|

565 | 426 |

|

|

JN15-D-12/31.5-210

|

210

|

544

|

655 | 516 |

|

JN15-D-12/31.5-250 | 250 | 624 | 735 | 596 | |

JN15-D-12/31.5-275 | 275 | 674 | 785 | 646 |

- Phone

- *Title

- *Content

Professional production line solution provider!

Sign up today for hints, tips and the latest product news - plus exclusive special offers.

Tel:+0086-18131539058

We don’t do spam and Your mail id is very confidential.